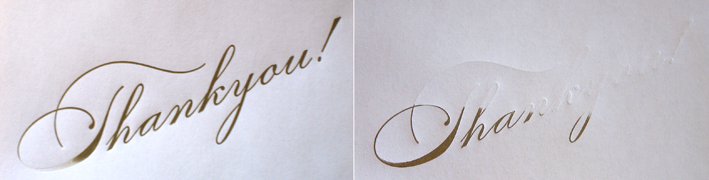

I had a serious printing session today. I've been having problems inking plates and was determined to get to the bottom of it. Here's what my prints were turning out like (click to enlarge):

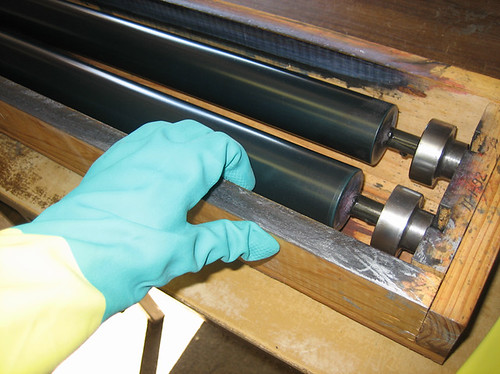

Either the ink cut-off midway, or there were bare strips. Such a basic printing issue, but no matter what I did I couldn't resolve it. So I bought new gloves that don't have any powder (to avoid trucks slipping on rails, or powder getting on rollers), and I clean everything up with turps and new rags: trucks, rollers, plates, base, rails and ink disc. This way I knew nothing had oil or powder on it. The trucks wouldn't slip on the rails or plate.

These are my trucks, taken off the rollers to have a thorough clean. Below shows how they slide back and forth on the rollers (which they don't do on the press).

These are my trucks, taken off the rollers to have a thorough clean. Below shows how they slide back and forth on the rollers (which they don't do on the press).

New gloves:

Taylor, the pressdog. She sleeps in her kennel next to the press, and on hot days she sits in her tub of water while I print.

My rails have vinyl tape wrapped tight at each end. I cleaned these off, and put the red PVC tape back on, as I've had set up for a while.

I recently found a large bolt that was loose as well, so I got right under the press and tightened it up. I ended up looking for it when the press started clunking on each impression. If this happens, firstly check to make sure that you haven't over-packed the platen. These presses are pretty hardy, but you don't want to strain them too much. Hard packing is optimal. Lots of soft packing just allow the type/plate to create an emboss on the back.

Cleaning everything thoroughly to remove oil, ink and dust, as well as readjusting the tape on my rails fixed my printing issues.

So if you are having trouble getting the rollers to ink up your plate, you need to check:

- rollers are level their entire length, preferably with calipers,

- plate and base are flat,

- base is locked into chase flat (not one side higher or lower than other),

- tape on rails is at proper height and are free of debris and oil, and

- trucks are free of debris and oil.

Of course there are probably a dozen other things, but I'm still learning that myself, too.

I have a lot of people asking me about uneven inking problems on tabletop presses. This is even tricker to troubleshoot because of how easily the impression knobs can be adjusted. This old posting might be of help.

More photos. This is my oilcan. Not terribly exciting, but I highly recommend you aquire a good one if you have a standing press. I can usually find between 35-42 oil holes on the press, and some of them are quite hard to get at.

I bought a new pot o' gold today (wow, if only it were that easy). The exact gold that I was looking for was out of stock at Prestons, so I grabbed this Pantone 871 instead. Not really happy with how it turned out on my stock, it's very dull, more so than the silver is.

I learnt today that if you tap a hole in the middle of the lid, it's easier to remove it. When the lid is on, just put a bit of tape over it.

The gold looked great on the press:

Lastly, a big shoutout to Sarah in Sydney who rang today, Gina in Canada who's bought out my etsy shop (and I've already had people asking Where did they all go??), Donna in Brooklyn who I'm printing business cards for, and Helen from Pepperina Press who helped me last night on etsy.

5 comments:

Great post! I have noticed that whenever I have that inking issue it's almost ALWAYS the tape on my rails. I found I was using the wrong kind and with the changes in temperature they would fluctuate and also over time they would flatten. I am now using a sort of plastic tape that is thick.It doesn't fluctuate or need adjusting since I've put it on. We'll see how it goes!

I think I need to get better tape too. I'm currently using PVC, which is great in normal weather, but as soon as it heats up the adhesive slides around and the tape flattens out.

Okay so Im yet to use my press ( shame on me!!) what does the tape do????

Heh, Mr Prestons told you that about the hole in the lid as well, did he? Sounds great, but then you try using his special can-opener thingy and dent the crap out of the lid, which never fits properly again. GAH.

In his world cans are opened only once, contents shoved in a huge press, and used up in one hit. I think the hole in the lid is quite a good idea, but the opener thingy is TEH EVIL and I will never use it again. I use a screwdriver under the rim, and once the lid's been opened a couple of times, you can give it a quick downwards whack on the edge of a [metal] work surface and it comes off easily. Impresses people, too. :)

haha, &Duck yes it was Mr Prestons. And yes, turns out the hole doesn't make much difference with the can-opener. Man, I've created some serious bruises trying to use that thing. Will be pinching your screwdriver crowd-pleaser from now on.

Screamingcactus - Putting tape on the rails lifts the rollers up heigher off the plate, so you can adjust how well it distributes the ink. Sounds simple, but it's not always easy getting the right amount of tape, especially when you change types of plates.

Post a Comment